References

Pre-contract manager – vessel newbuild

Fram Marine has been engaged for Project management of the pre-contract phase of a scientific, support and ROV vessel, with high class accommodation. The vessel is to be designed, engineered and built by Vard. Main tasks performed was to support and verify the development of technical documentation before contract signing and to front load the project, for rapid start including evaluation and nomination of main and medium equipment and suppliers.

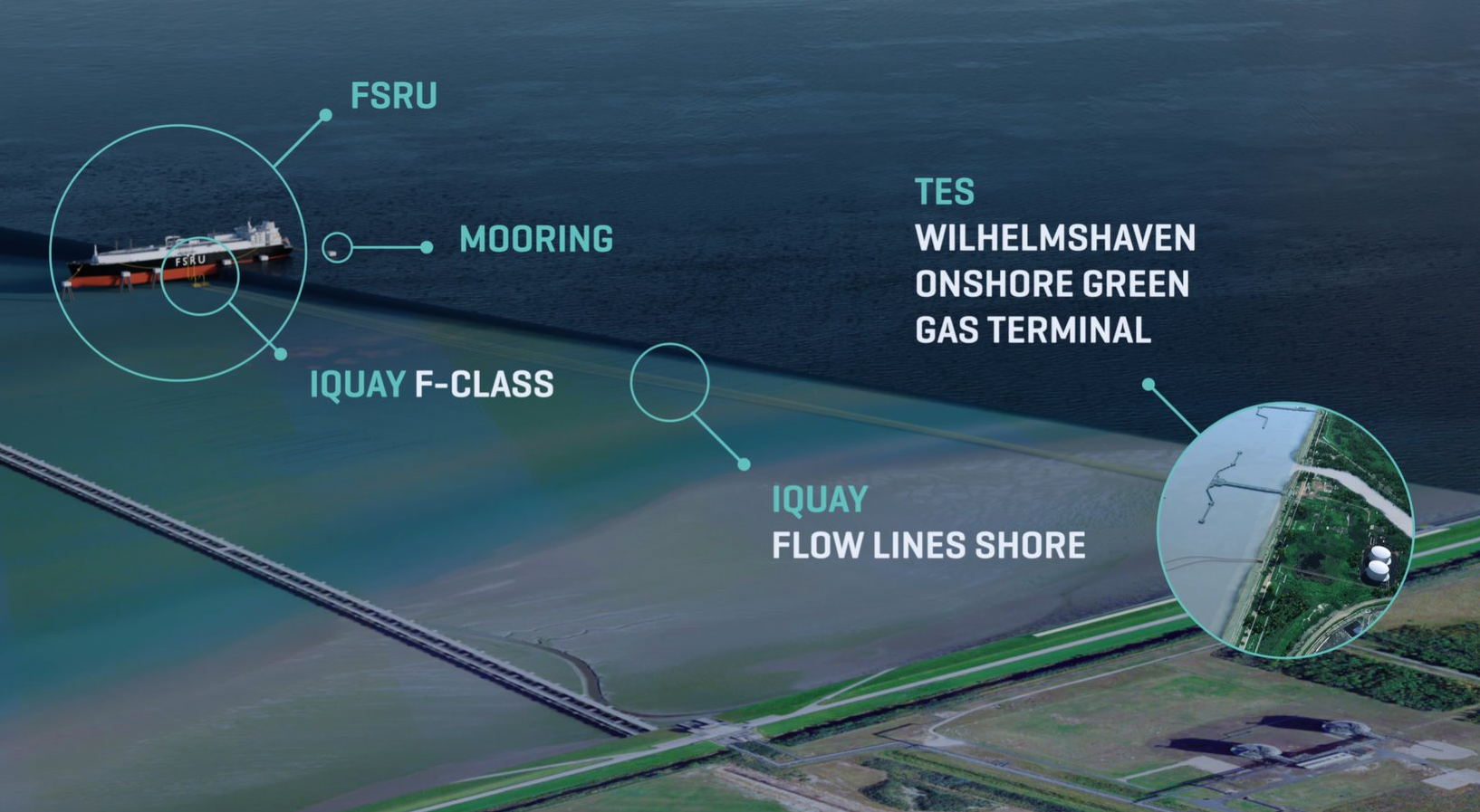

ECONNECT Energy – Jettyless Transfer

Fram Marine assisted ECOnnect Energy with the fast-track IQuay F-Class jettyless system for the Wilhelmshaven project. Given the project's tight timeline and the innovative nature of the solution, regulatory requirements evolved throughout. Fram Marine's role focused on coordinating and managing the offshore preparations for full-scale testing of the Gas Balcony emergency release system, including the connection of risers and installation of the gas balcony on the FSRU.

Hurtigruten – Environmental upgrades

Fram Marine engaged for site supervision and site management in relation to environmental upgrades on four of Hurtigruten’s coastal fleet vessels. The upgrades was part of required enhancements required for coastal trading along the Norwegian coast. Scope included follow up on full dry docking scope for the vessels during yard stay.

World Wide Wind

Fram Marine has been engaged with the project management execution for the development of World Wide Wind’s first contra-rotating floating wind turbine prototype. This role involved managing the entire process, construction, and offshore testing of a 30 kW vertical axis wind turbine prototype. Additionally, Fram Marine is contributing to the development of a commercial-sized wind turbine in collaboration with experienced industrial partners, providing essential project management and technical expertise to drive the successful implementation

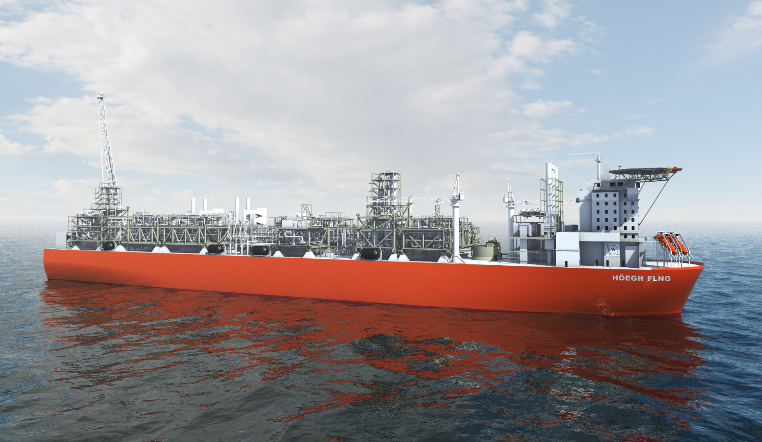

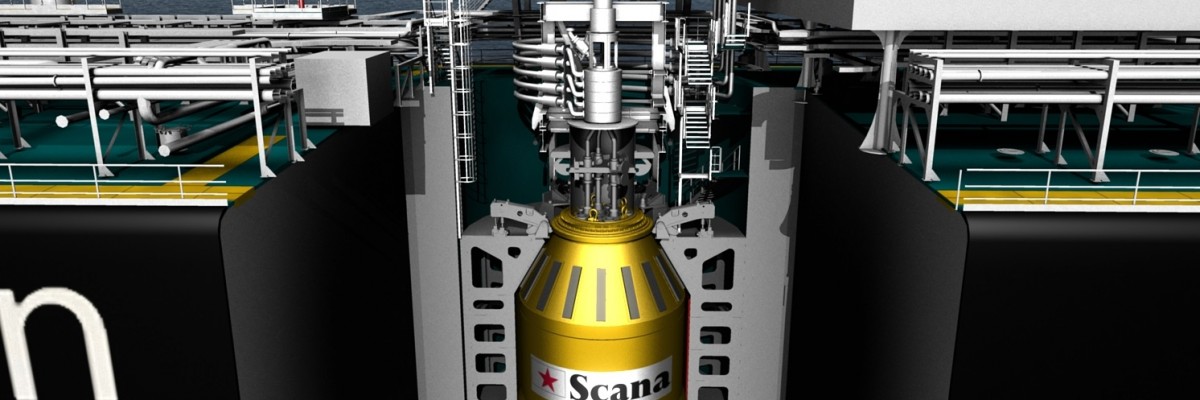

Höegh EVI

Fram Marine has been a key member of Höegh EVI's project execution team for several years, contributing to the deployment and development of multiple fast track FSRU (Floating Storage and Regasification Unit) projects. Fram Marine has served central roles, including engineering manager, technical manager, and project control, ensuring seamless integration and successful execution throughout the project lifecycle.

Klaveness Combination Carriers

On behalf of KSM, Fram Marine was engaged for project management in retrofitting Air Lubrication Systems (ALS) on two of their combination carriers, where first vessel was being the pilot vessel for KCC on this technology – 1MW shaft generators was installed to drive the air bubble lubrication system. Business Case and analysis of Wind Propulsion alternatives was also performed.

Crown LNG

Fram Marine was engaged by Crown LNG to manage the technical, engineering, and operational execution of the Kakinada LNG regasification project, located 19 km offshore from Kakinada, India. As part of Crown LNG's vision for a digitally advanced regasification platform, Fram Marine also led the digital initiatives aimed at increasing operational efficiency through innovative technologies and data-driven solutions.

Astrum Group – Chemical recycling plant

Astrum Group is an early-stage ESG company planning to develop chemical recycling facilities for plastic waste in Europe. The company was in an early phase and needed deeper technical expertise and engineering capacity for the planning and design of the first factory. Fram marine assisted the company with organizational resources, technical know-how, and experience to move from initial idea through feasibility into execution.

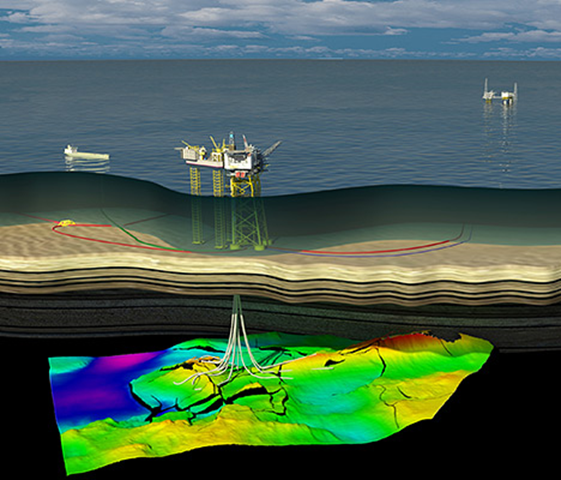

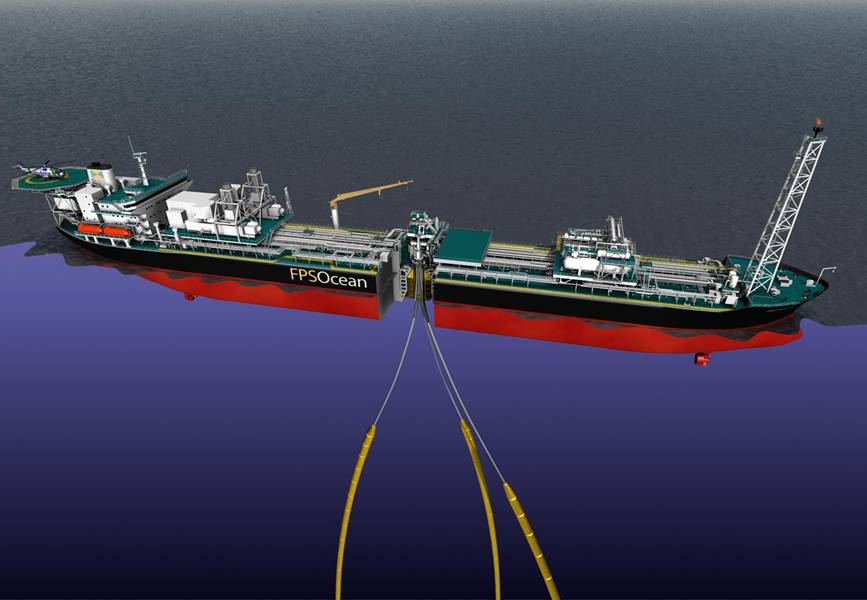

Equinor-BSOI-STS solution

Fram Marine was engaged by Equinor to deliver a study report on a possible STS operation in the Sarnesfjorden Area, “Ship – to – ship operations in Sarnesfjorden”. The purpose of the study was to provide sufficient input to the concept studies and logistic model to assess what would be the most cost-efficient logistic solution.

Clean Marine EGCS production

New IMO regulations entering into force 2020 related to air emissions lead to a very high demand for SOx purification equipment for cleaning exhaust gas from large vessels, also known as "scrubbers". The growth demanded fundamental changes of the Clients's work processes, project execution model (PEM) and product management.

DolWin Alpha converter station

The 800MW DolWin1 HVDC Offshore Converter Station connects offshore wind farms located in the North Sea DolWin1 cluster to the German national grid. ABB engaged Fram Marine to manage all technical aspects related to close-out activities after handover to their client TenneT.

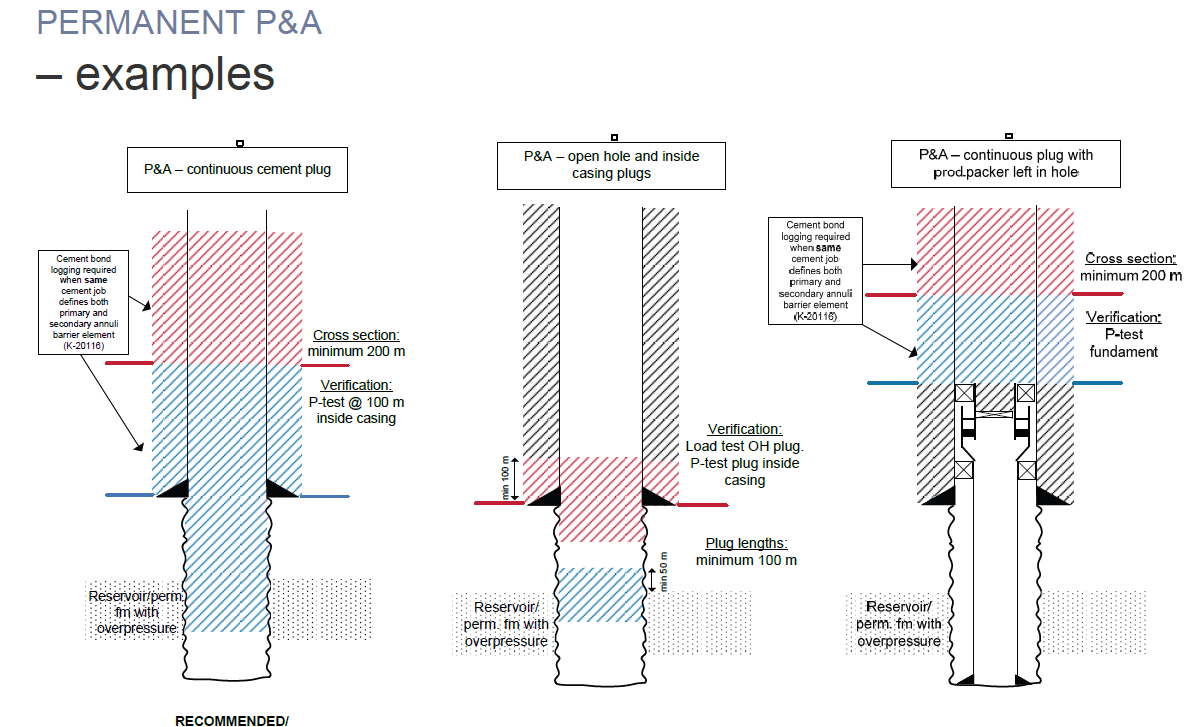

Drilling Rig Marked Evaluation

Advisory services related to screening and evaluation of the Drilling Rig market.

Do you have any questions or specific needs?

Please feel free to contact us to explore how our expertise can assist you. We look forward to hearing from you!